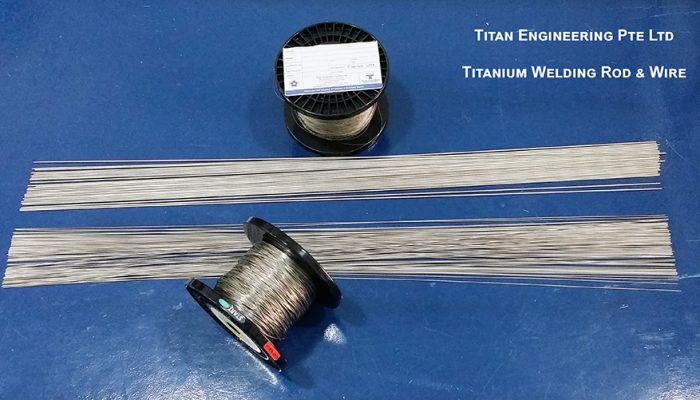

TITANIUM WELDING RODS AND WIRES

Titanium TIG Welding rod, MIG Weld Wires to the titanium welding process are available with us. Titanium welding wire and rod is covered by AWS A5.16-70 Specification (“Titanium and Titanium-Alloy Bare Welding Rods and Electrodes”). It is generally good practice to select a filler metal matching the properties and composition of the titanium base metal grade. However, for both commercially pure grades and alloys, selecting a weld wire one strength level below the base metal is also practiced.

Titanium TIG (tungsten inert gas) rods provide filler metal for welding titanium. Also known as TIG cut lengths, they are fed into the weld joint to add material for building up the weld. The heat from the GTAW (gas tungsten arc welding) process melts material from the rod and the workpiece, and the molten material fuses to create the weld.

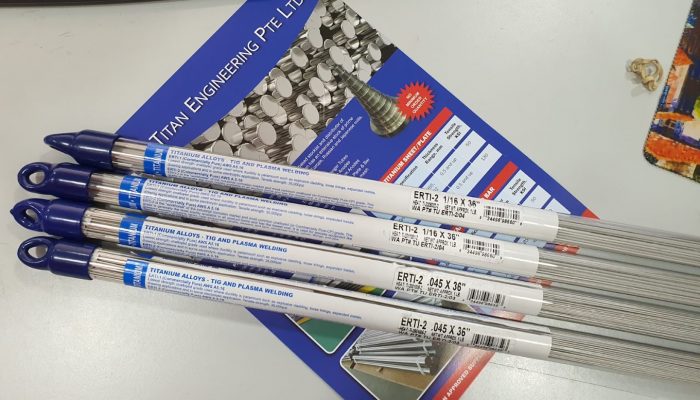

AWS Spec. A5.16, Class ERTi-2 (CP-Ti Commercial Pure). Titanium TIG Welding rods in grades ERTi-1 and ERTi-2 specs are TIG and MIG filler metals used for welding commercial pure titanium alloys commonly found in applications requiring high-temperature resistance and resistance to chemical reagents. Although there are four grades of Commercial Pure Titanium filler metals, C.P. Grade 2 (ERTi-2) is the most popular because of its good balance of strength, formability, and weldability.

Contact us for your Titanium TIG Welding rod welding rod requirements.

Indonesian customers can contact our Jakarta office.

Cleanness Is Critical When TIG Welding Titanium: Welding titanium tubing requires extreme cleanness—the base metal, filler metal, and welding environment must be immaculate. Contamination by natural body oils, oils from the forming and drawing process, shop dust, paint, dirt, cutting fluids, and lubricants all can lead to embrittlement and weld failure.

Titanium is a reactive metal that interacts readily with oxygen, making it prone to oxidization and contamination, and making it difficult to weld. However, meticulous preparation, a steady hand, and lots of practice lead to successful welds.

What is the Technical Difference between Welding and Wedding? – Not much; both are joints, in a way.

In Welding, there are sparks first and bonding forever.💕

In Wedding there is bonding first and sparks forever.✨