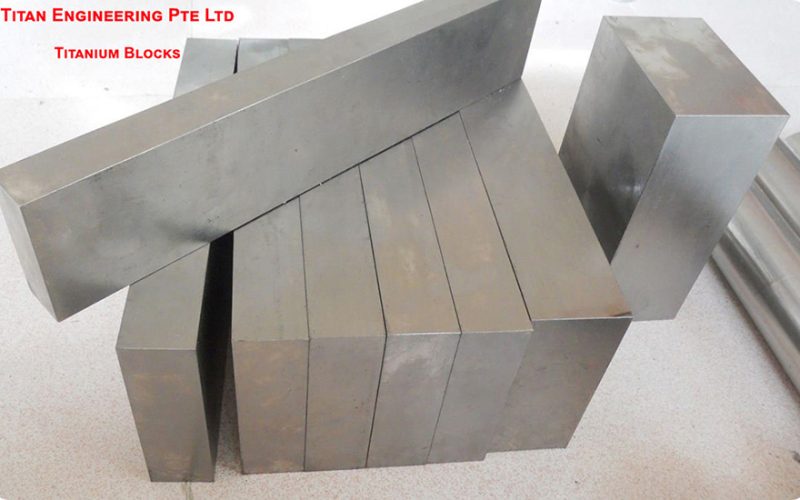

TITANIUM – CP GRADE MATERIAL

Commercially pure, or CP titanium is unalloyed titanium with a purity range of 99.0% to 99.4%. The term commercially pure (CP) titanium is applied to unalloyed titanium and designates several grades containing minor amounts of impurity elements, such as carbon, iron, and oxygen. CP Ti Gr. 1 has the highest corrosion resistance, formability, and lowest strength, whereas, CP Ti Gr. 4 offers the highest strength with moderate formability. The most commonly used grade is CP Ti Grade 2. Titanium Grade 2 has moderate strength with excellent cold formability, and weldability is widely available. CP Titanium’s mechanical properties are controlled by chemistry; specifically the input of Nitrogen, Oxygen, and Iron which will increase the strength of the material.

CP Grade 2 Titanium, JIS H 4600 TP340, TP270C, TP340C, TP340H, TB340 is the most commonly used grade in CP grades titanium. TP340, JIS Pure Titanium grade is having tensile strength of 340 ~ 510 MPa.

| Chemical compositions of the four grades of CP titanium are listed below. | ||||

|---|---|---|---|---|

| Ti Gr 1 | Ti Gr 2 | Ti Gr 3 | Ti Gr 4 | |

| Nitrogen, max. | 0.03 | 0.03 | 0.05 | 0.05 |

| Carbon, max. | 0.03 | 0.10 | 0.10 | 0.10 |

| Hydrogen, max. | 0.03 | 0.01 | 0.01 | 0.01 |

| Iron, max | 0.03 | 0.30 | 0.30 | 0.50 |

| Oxygen, max. | 0.03 | 0.25 | 0.35 | 0.40 |

| Titanium | 0.03 | bal. | bal. | bal. |

| Yield strength (MPa) | 0.03 | 275 | 380 | 485 |

| Ultimate strength (MPa) | 0.03 | 345 | 450 | 550 |

| Elongation (%) | 0.03 | 20 | 18 | 15 |

Commercially pure titanium is immune to general corrosion in seawater and brackish water to temperatures as high as 130 0C. Low levels of alloying additions such as palladium in the case of Grades 7, 11, 16 and 17 or Ni & Mo in the case of Grade 12 will extend general corrosion resistance to temperatures in excess of 260 Deg C.

Crevice corrosion

Commercially pure titanium (Grades 1, 2, and 3) is immune to crevice corrosion in aerated seawater to temperatures of at least 70 0C. In deaerated seawater commercially pure titanium will resist crevice corrosion to temperatures as high as 94 0C. When higher service temperatures are required or crevices cannot be engineered out of the process equipment titanium grades containing alloy addition can be applied to provide protection from crevice corrosion. Titanium grades containing additions of palladium such as Grades 7, 11, 16 and 17 or titanium Grade 12 containing small additions of nickel and molybdenum are economical choice to enhance protection from crevice corrosion. Titanium Grade 7 is used to fight crevice corrosion.

| Titanium Grade 2 - Physical Properties | |

| Density | 0.163 lb/in3 |

| Ultimate Tensile Strength | 62.4 ksi |

| Yield Tensile Strength | 49.3 ksi |

| Shear Modulus | 5,510 ksi |

| Shear Strength | 55.1 ksi |

| Fatigue Strength | 40.6 ksi |

| Hardness Rockwell | Brinell | B89 | 180 |

| Elongation at Break Percentage | 26% |

| Reduction of Area | 34% |

| Modulus of Elasticity | 14,800 ksi |

| Poisson's Ratio | 0.34 |

| Machinability Percentage | 75% |

| Melting Point | 2,930-3,020 °F |

| Specific Heat | 1.3 x 10^-1 BTU/lb-°F |

| Thermal Conductivity | 156 BTU-in/hr-ft^2-°F |

| Electrical Conductivity | 3.6% IACS |

JIS Standard Titanium

| Material Form | Standard | Specification | Process | Density g/cm3 |

| Sheet | JIS H4600 | TP270C | Cold Rolling | 4.51 |

| Sheet | JIS H4600 | TP340C | Cold Rolling | 4.51 |

| Plate | JIS H4600 | TP340H | Hot Rolling | 4.51 |

| Bar | JIS H4650 | TB340C | Cold Rolling | 4.51 |

| Bar | JIS H4650 | TB340H | Hot Rolling | 4.51 |

| Bar | JIS H4657 | TF340 | Forging | 4.51 |

| Heat Exchanger Pipe | JIS H4631 | TTH340W | Welded | 4.51 |

| Piping | JIS H4635 | TTP340W | Welded | 4.51 |

Contact Titan Engineering Pte Ltd or our Jakarta Branch PT.Special Metals Indonesia for your titanium requirements.

Engineering Law: Any fabrication drawing must contain at least one part which is obsolete and two parts which are unobtainable.😊